ProLogium Technology announced a partnership with Germany's FEV Group at CES 2026 to showcase next-generation solid-state battery technology. The companies will present a concept EV battery module targeting approximately 1,000 km driving range, advancing toward OEM readiness through vehicle program evaluation.

The module uses ProLogium's proprietary superfluidized all-inorganic solid-state lithium ceramic battery technology. Designed for high energy density, ultra-high safety, fast-charging capability, and excellent low-temperature performance, the system has already reached sample car-ready stage.

Solid-state batteries replace liquid electrolytes with solid materials, offering improved safety and greater energy potential per cell. Without flammable liquid components, they are less prone to overheating or leakage, addressing critical safety concerns in the EV market.

China recently unveiled the world's first national standards for solid-state batteries, describing the technology as the "dream battery" for its transformative potential. The standards specify energy density thresholds and testing protocols, aiming for mass commercialization within two years.

Multiple Chinese automakers have accelerated solid-state battery development. Guangzhou Automobile Group commissioned a pilot production line with energy density exceeding 400 Wh/kg in November 2025, while Chery unveiled its Rhino S module with 600 Wh/kg density supporting over 1,200 km range.

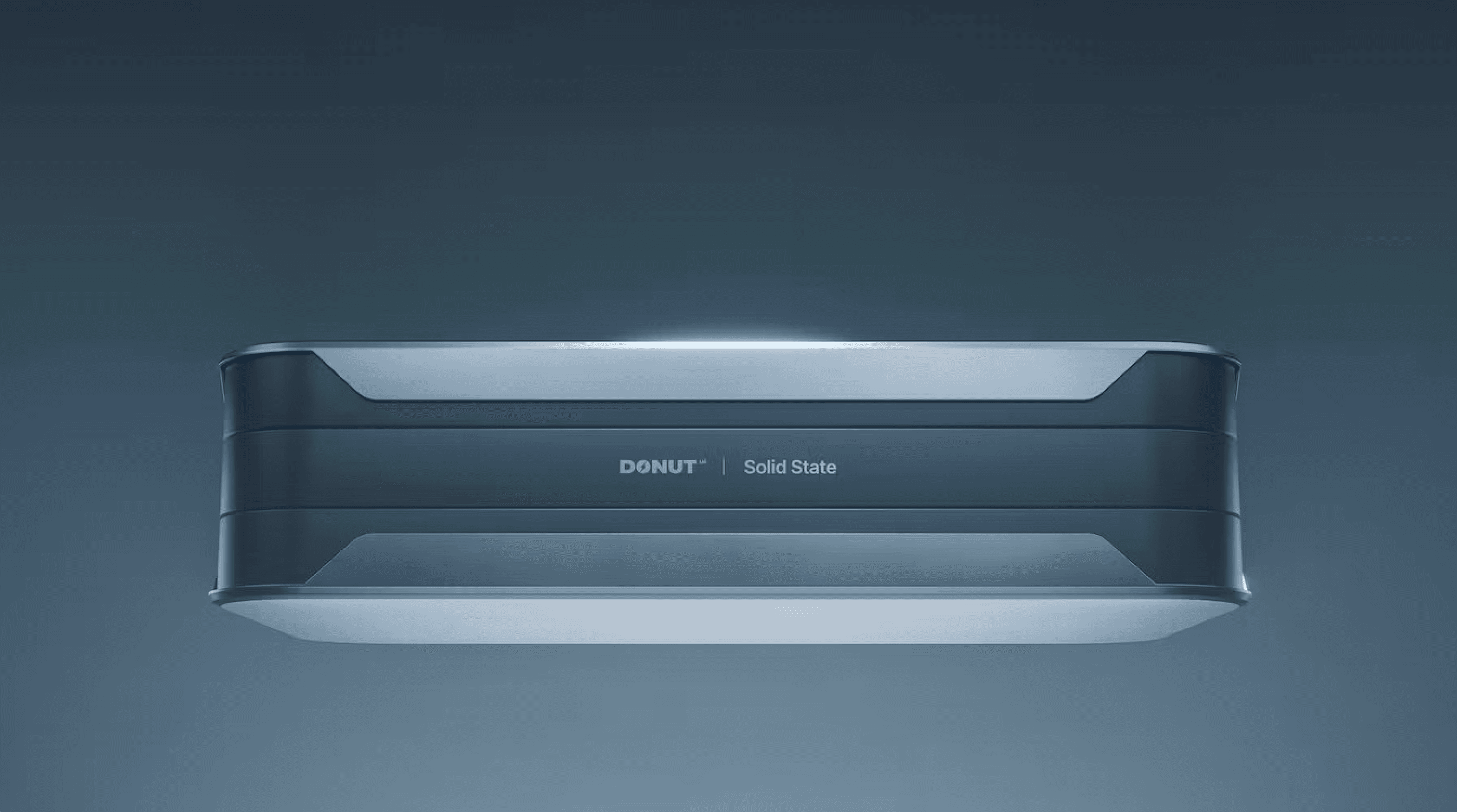

Finland's Donutlabs announced the world's first production solid-state battery rated at 400 Wh/kg. Verge Motorcycles incorporated the technology into its TS Pro and TS Ultra models, achieving up to 600 km range with 80% charge in less than 10 minutes using 200 kW charging.

Verge's solid-state battery motorcycles deliver 370 miles of range and ten-minute charging capability. The company became the first to introduce solid-state technology into production motorcycles, with deliveries scheduled for coming months.

According to industry analysis, current estimates indicate solid-state batteries remain 3-5 times more expensive than conventional lithium-ion batteries. Manufacturing requires strictly controlled dry rooms immune to moisture and oxygen, necessitating specialized equipment and keeping costs high.

Industry forecasts suggest solid-state batteries might begin entering mainstream commercial use by the early 2030s. For the first few years, they will likely be limited to high-end vehicle models where premium costs can be absorbed by less price-sensitive buyers.

The global solid-state battery sector underwent marked acceleration in 2025, with particularly notable progress in China. Technological breakthroughs, production line deployments, and industrial collaboration drove rapid advances in key materials and cell development.

Beyond electric vehicles, solid-state batteries' high energy density and improved safety characteristics make them suitable for drones, electric vertical take-off aircraft, grid energy storage, consumer electronics, and humanoid robots. Their stable operation across temperature extremes expands potential applications.

Chinese researchers have developed self-adaptive interphases that maintain contact between lithium metal anodes and solid electrolytes without external pressure. This breakthrough overcomes a major hurdle in solid-state technology, paving the way for more reliable and efficient batteries.

The transition to solid-state batteries will reshape raw material demand. The technology may create new opportunities for nickel suppliers as ultra-high-nickel cathode materials enhance performance. Batteries will likely shift toward lithium metal anodes instead of conventional graphite to increase energy density.

Lithium consumption in sulphide-based solid electrolytes can be more than eight times that of conventional liquid lithium-ion batteries according to industry estimates. In the transition period before lithium metal anodes are widely adopted, manufacturers are expected to increase use of silicon-carbon anode materials.

China's new energy consumption rules effective January 1, 2026 cap efficiency for two-tonne models at 15.1 kWh per 100 km. These regulations push for smarter designs rather than larger batteries, combining with solid-state advancements to make EVs more accessible and efficient.

BYD recently overtook Tesla as the world's top EV seller, attributed to China's efficient manufacturing and regulatory edge. The country's focus on battery safety and efficiency forms part of a broader strategy to bolster technological sovereignty amid international scrutiny.

Industry confidence remains strong despite production scalability and cost barriers. Government support continues to materialize, though the timeline for large-scale commercialisation depends on technical progress and cost trajectories, clouding the outlook for widespread adoption.