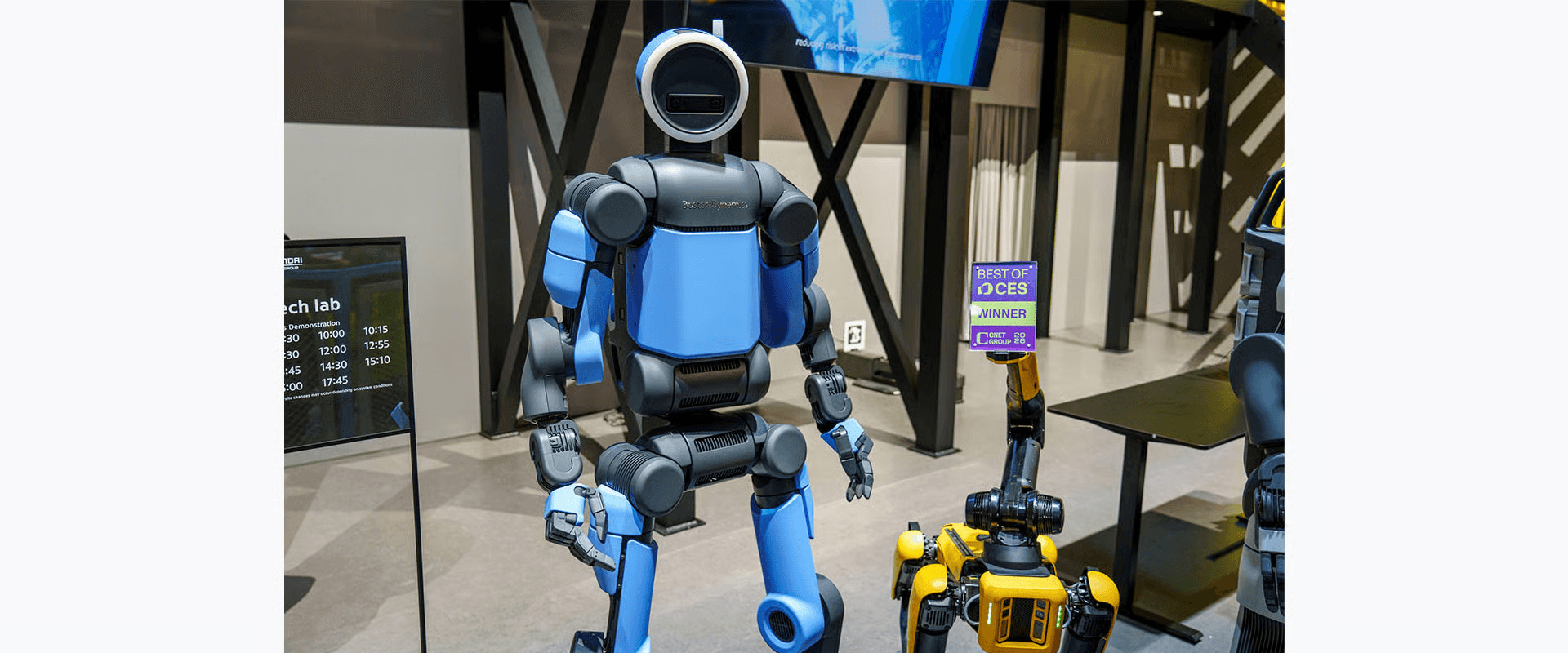

Hyundai will deploy 30,000 Boston Dynamics Atlas humanoid robots across its factories over the next decade, the automaker announced at CES 2026. The production-ready Atlas units begin shipping this year to Hyundai and Google DeepMind facilities, with mass production scaling to 30,000 robots annually by 2028.

The 6.2-foot humanoid demonstrated its agility at the Las Vegas trade show with a backflip that showcased 56 degrees of rotational freedom. While the robot completed the midair rotation, it stumbled on landing and lost a hand cap, revealing the challenges of perfecting complex maneuvers on factory floors.

Atlas features human-sized hands with tactile sensing and can lift 50kg payloads repeatedly. Its four-hour battery swaps automatically in under three minutes, enabling continuous operation in temperatures from -20°C to 40°C. The robot operates through three control modes: fully autonomous, tele-operated, or tablet-managed.

Hyundai's $26 billion robotics investment includes a US factory capable of producing 30,000 units yearly. The automaker's majority stake in Boston Dynamics enables deep integration, with Hyundai Mobis supplying actuators and Hyundai Glovis optimizing logistics for the robotics platform.

Google DeepMind's Gemini AI powers Atlas's navigation and decision-making capabilities. The partnership focuses on teaching robots new tasks quickly, with knowledge instantly deployable across the entire fleet. This AI integration aims to transform Atlas from hardware-driven robotics to adaptive, intelligence-driven systems.

Initial deployments in 2026 will focus on parts sequencing and material handling at Hyundai's newly opened Georgia metaplant. By 2028, Atlas robots will handle repetitive sequencing tasks, progressing to complex assembly work by 2030. The Robot Metaplant Application Center opens this year to train robots through iterative processes combining simulated and real-world data.

Hyundai's robotics strategy extends across its group affiliates Kia, Hyundai Mobis, and Hyundai Glovis. The company aims to establish an end-to-end AI robotics value chain, applying automotive manufacturing expertise to standardize components and build scalable production systems.

The Atlas rollout comes as Chinese competitor UBtech deploys Walker S2 humanoids across automotive assembly and logistics sectors. Both American and Chinese manufacturers are taking methodical approaches to large-scale humanoid deployment, signaling intensified competition in industrial robotics.

Robert Playter, CEO of Boston Dynamics, called Atlas "the best robot we have ever built." He emphasized the company's 30-year history in advanced robotics and described the humanoid as marking "the first step toward useful robots that can walk into our homes." The commercial Atlas robot represents a significant milestone in the evolution of humanoid robotics.

Hyundai acknowledges that Atlas deployment may displace some human jobs but says workers will be needed to train and supervise the robots. The company positions the technology as enhancing human-robot collaboration rather than replacing human workers entirely.